How to Cut Production Time in Half with a Digital Textile Color Program

5 min read

How to Cut Production Time in Half with a Digital Textile Color Program

Fashion and Apparel Colorists can get to approved colors faster and more efficiently while dramatically decreasing the textile industry’s environmental impact by leveraging more digital tools to specify and communicate color as a part of their color program.

Challenges

Colorists are faced with several challenges as the coordinators of the entire portfolio of color throughout the textile supply chain, including:

- Designers present ideas based on fashion trends without much thought of color achievability, but most brands don’t have the budget to achieve all the top trending colors presented on the runways in Paris and New York.

- Color achievability varies on solid mixed media across multiple suppliers simultaneously, so each new color requires a lab dip from the supply chain. Shipping physical samples or representatives around the world for review is expensive and time-consuming, and dyeing rework contributes to air and water pollution.

- With a push for fast fashion and increased consumer demand for more sustainable practices, colorists are under a lot of pressure to work faster and smarter.

Solution

Leveraging digital color data from a fleet of calibrated spectrophotometers that have a tight inter-instrument agreement, formulation software, QC, and QA software, colorists can holistically manage a textile color from concept through formulation much faster, often with a single round of lab dips.

Results

By introducing spectral data and color digitization in the design-to-manufacturing workflow, colorists can get to approved colors faster and more efficiently.

- Reduce lab dip, shipping, and review time from 40 to 50 days to just 10

- Formulate, produce, finish, evaluate quality, and ship in just 6 days instead 30 to 40

How It Works

The process starts with a digital database of approved brand color palettes that clearly defines technical and appearance specifications for each media, such as cotton, nylon, and polyester. The colorist communicates this digital color data and an acceptable tolerance to the supplier(s), who enters the digital data into formulation software to quickly calculate an accurate recipe. After dying a fabric sample, the supplier measures it with the spectrophotometer to ensure it is within a tolerance of the brand standard and sends a physical lab dip to the colorist for review.

The colorist measures the lab dip and enters the color data into quality assurance software to compare against the digital color specification and make intermediate decisions on metamerism. If the lab dip is within tolerance and visually matches the other components, the supplier gets a green light to begin production. If not, the colorist can provide specific L*a*b* direction on how to adjust the color and even run QA reports to help suppliers improve their processes.

Featured Products

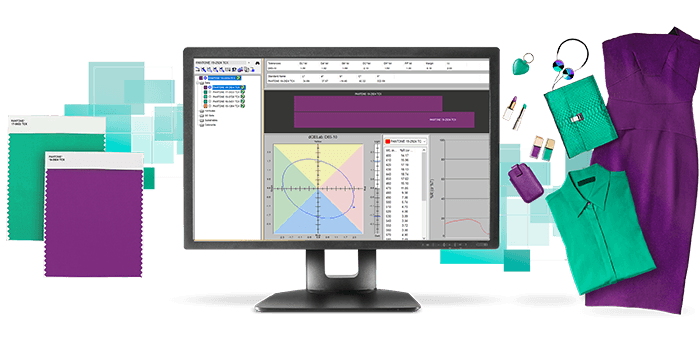

PantoneLIVE Production – Plastic, Coatings, and Textile

A cloud-based database that offers instant access to spectral colors and brand palettes for cotton, nylon, and polyester applications. These standards can be used during design, formulation, and quality control.

Ci7800 or Ci7860

Benchtop sphere spectrophotometers with the tightest inter-instrument agreement and repeatability available to capture precise color data and generate accurate digital color standards.

NetProfiler

Quality assurance software to ensure all onsite and offsite instruments are measuring within tolerance and performing within specification.

Color iMatch

Formulation software to achieve initial matches up to 50% faster, cut correction steps in half and identify ways to rework leftover materials for a more sustainable formulation process.

Color iQC Professional

Quality assurance software to verify color quality and consistency and generate color data performance reports for a real-time view of production quality.

Achieve Color Success

To continue to compete in the textile industry, apparel companies must accelerate speed to market, bridge the art and science of design, and master digital color. Applying digital color management throughout the design, formulation, and quality control processes provides a seamless way to produce accurate color and reduce the carbon footprint of the textile industry.

Leave a Reply

Your email address will not be published. Required fields are marked *